Chemical pumps play an essential role in many industries. They are able to provide secure and efficient transfer mixing, dispensing and mixing of chemicals. They are specifically designed to handle corrosive or abrasive fluids that cannot be accommodated by conventional pumps. Chemical pumps are classified into positive displacement and centrifugal pumps.

Partnering with reputable chemical pump manufacturers will ensure access to top-quality pumps that meet stringent industry standards. They leverage their experience in the design and production of robust, durable and effective chemical pumps. To withstand chemicals that are corrosive or abrasive they utilize advanced technologies and materials, manufacturing processes, and other methods. By working with trusted manufacturers, businesses can access pumps that are able to stand up to harsh conditions and perform perfectly.

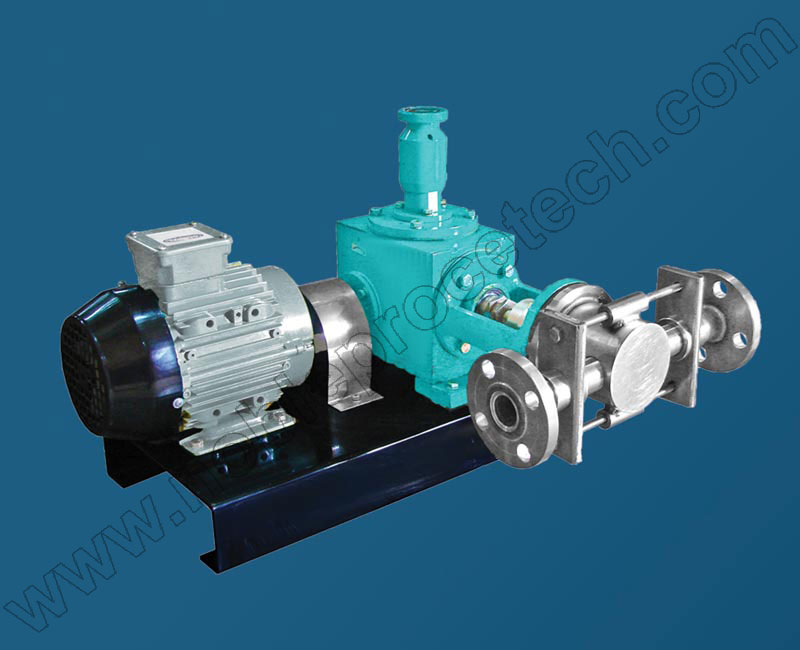

Manufacturers of chemical transfer pumps are experts in the design of pumps specifically crafted to work with fluids. These pumps are capable of handling various chemicals like sulphuric and acetic acids including sodium hypochlorite as well as other. With the goal of maximizing fluid handling, chemical transfer pump manufacturers create pumps with characteristics like corrosion-resistant materials seals, leak-proof seals, as well as precise flow control systems. They are specifically designed to ensure smooth, safe and precise chemical transfers. For more information, click chemical manufacturing pump

Chemical pump suppliers are vital in helping businesses find the best pumps that meet their requirements. They provide a wide range of pumps for chemical use from reputable manufacturers. They provide comprehensive product catalogues as well as technical knowledge to help companies select the best pumps for their needs. Chemical pumps offer an array of options to businesses so they can select the ideal pump for their needs.

Chemical pumps are essential to more than just fluid protection. They are critical for maintaining the integrity and safety of the entire industrial process. Unreliable or malfunctioning pumps can cause costly leaks and inefficient operation, and even dangers. Pump failures can have dire consequences for industries that use chemicals, such as chemical manufacturing and petroleum chemicals.

By purchasing chemical pumps that are durable companies can reduce the risks associated with fluid management. They are designed to withstand the corrosive qualities of chemical. They are therefore able to operate continuously and reliably for a long period of time. The pumps feature features such as sturdy materials and sophisticated seal mechanisms. They also offer exact flow control.

In addition, many chemical pump come with a comprehensive support and maintenance. The manufacturers and suppliers are aware of the importance of these pumps, which is why they provide technical support along with spare parts as well as regular maintenance tests. This proactive approach allows for the detection and treatment of any potential problems prior to them becoming serious. It guarantees continued reliability of the pump, as well as minimizing unexpected downtime.

Chemical pumps are employed in a variety of industries, including food processing, petrochemicals and chemical manufacturing. These pumps are essential for fluid transfers, mixing and dispensing in these fields. Chemical pumps can also be found in high-temperature systems for heating and also in refineries. Their capacity and flexibility to handle difficult fluids make them essential equipment to ensure efficient and reliable industrial processes.

Consider factors such as fluid type, flow requirements and operating conditions when deciding the right chemical pump. Affirmed suppliers and manufacturers offer guidance and support in selecting the right pump for your specific needs. When making a choice it is crucial to think about the safety, reliability, and effectiveness to reduce the risk of accidents, maximize productivity, and reduce breakdowns.

The functions of chemical pumps in refineries extend beyond the limits of the facility in and of. The pumps are able to play a crucial role in off-site operations and contribute to the safe and efficient movement of chemicals in a variety of contexts. It could be transporting corrosive liquids to storage facilities, facilitating loading and unloading tanker truck as well as aiding repair and maintenance activities, chemical pumps are indispensable for ensuring that smooth operations are carried out beyond the refinery’s borders. Chemical pumps are necessary in applications that require accuracy, safety, and efficiency when handling corrosive and aggressive chemical substances. Chemical refineries can enjoy smooth and reliable chemical transfer through investing in high quality chemical pumps and cooperating with reliable producers and suppliers.