Wire cleaners and wire rope lubricators are indispensable in the field of cable repair, where precision is key. They are vital for providing a smooth operation of cables and longevity in many industries. In this article, we delves into the importance of lubricating the wire rope and wire cleaners in cable maintenance, exploring their functions as well as the benefits and profound impact they play on the overall efficiency of operations.

Understanding wire Rope Lubricators

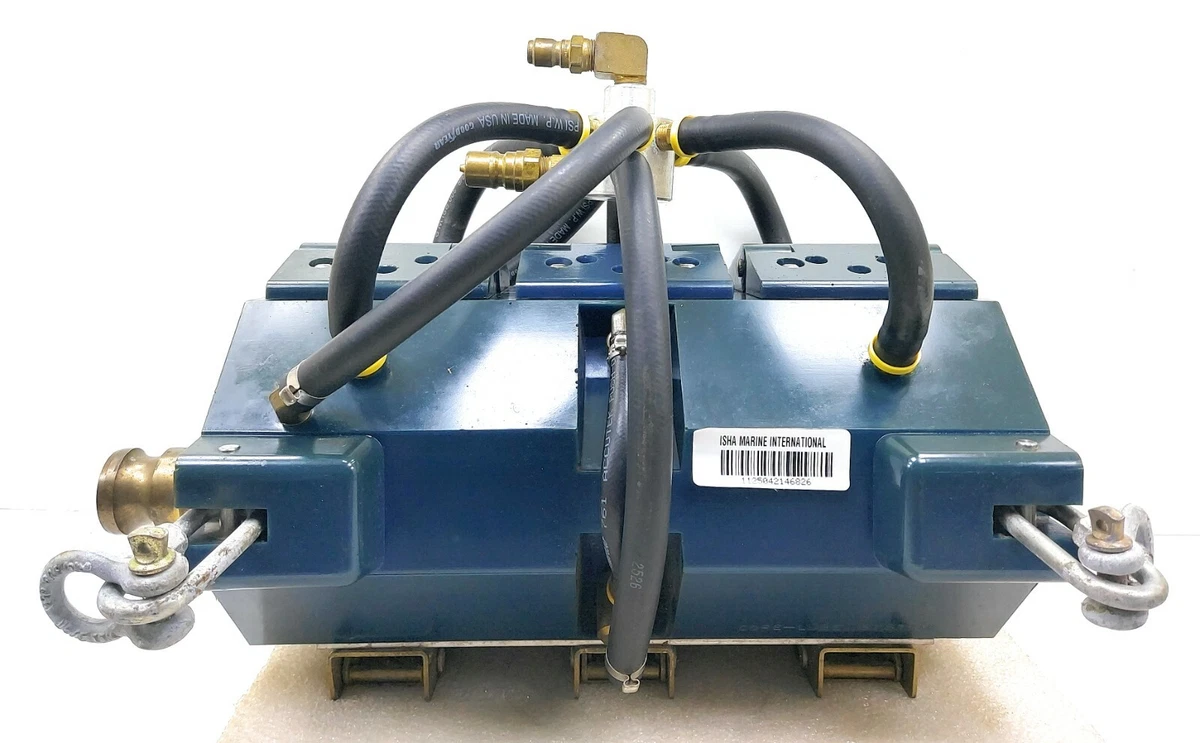

Wire Rope Lubricators are specialized machines designed to grease wire ropes in a systematic manner. This is essential to protecting against corrosion, reducing friction, and increasing the durability of the cable. The lubricator makes sure that the lubricant agent is evenly distributed along the length of the rope of wire, ensuring the most complete protection against wear and tear.

How to keep cables clean using wire cleaners:

Cleaners for wires and cable are both necessary to ensure clean cables. They are designed to remove contaminants, debris and liquids that could build up on the cable during different actions. In environments with harsh conditions, the use of wire cleaning products is vital to ensure the highest performance. Click here Wire Cleaning

Optimizing Cable Lifespan:

The use of lubricators for wire ropes as well as wire cleaners contributes significantly to increasing the longevity of cables. By applying lubrication in a systematic manner using wire rope lubricators and removing contaminants with wire cleaners, the cables are protected from the detrimental effects of friction, corrosion and other external elements. The integrity of the cable is maintained with the result of improved efficiency in operation and lower maintenance costs.

Efficiency in Application

Wire rope lubricators are created to be simple to operate and efficient in their use. They can be employed on different sizes and types of wire ropes, offering versatility in maintenance techniques for cables. The systematic and automated application of lubrication ensures consistency and eliminates the possibility of inconsistency that manual processes could create.

In a challenging environment, adaptability:

In the fields where cables are exposed challenging environments, such as those in drilling, construction, or maritime operations, the adaptability of wire rope lubricators or wire cleaners is particularly crucial. They have been developed to be able to withstand harsh conditions. They are, therefore, reliable equipment for maintenance of cables.

Cost-Effective Maintenance Solutions for

In the long term, using wire cleaners and lubricators for wires to maintain cables is a good method. The initial investment in these tools is minimal compared to the possible costs like cable replacements and repairs because of poor maintenance.

Conclusion:

Wire rope lubricators as well as cleaners of wires, are the guardians of cable integrity. They provide high-quality, long-lasting and efficient performance across a variety of industries. Cleansing away pollutants and the application of lubricants helps in the preservation and longevity of cables. This makes maintenance easier and enhances the efficiency of operations. In a field that depends on cables to carry out critical processes, investing in advanced tools for maintaining cables such as wire rope lubricators, or wire cleaners isn’t just an excellent choice, but is also essential.