When it comes to increasing efficiency and performance of engines, the quality of fuel plays a significant role. Diesel fuel may be contaminated over time with sediment, water and Microbial growth. This could negatively impact engine performance and lead to costly repairs. Fuel polishing is a great way to make sure that your engines operate without a hitch and to combat contamination of fuel.

Polishing of fuel (also called diesel polishing) is the method to remove pollutants from diesel fuel. Polishing fuel is a service carried out by experts using modern technology and equipment to restore fuel to its original form. In addition to removing harmful substances, and restoring fuel quality polishing fuel can improve the efficiency of your engine and reduces the cost of maintenance and extends the lifespan of the equipment.

There are numerous fuel polishing companies that can meet the needs of different industries that utilize diesel fuel. These services are provided by highly trained technicians with experience in fuel systems that understand the complexity of contamination in fuel. Their extensive knowledge and special tools let them identify fuel-related problems and apply the right methods to polish fuel.

The process of polishing fuel has as its principal goal elimination of sediments, water microorganisms and sludge out of diesel fuel. The accumulation of water within tanks for fuel can be caused through leaks or condensation which causes corrosion, fuel degrading as well as the growth and expansion of mold and bacteria. Sediment and sludge in contrast, can originate from impurities in the fuel or from the degrading of fuel components as they age. The contaminants can block filters and injectors as as other important components. This could result in an impairment in the performance of engines or even a breakdown.

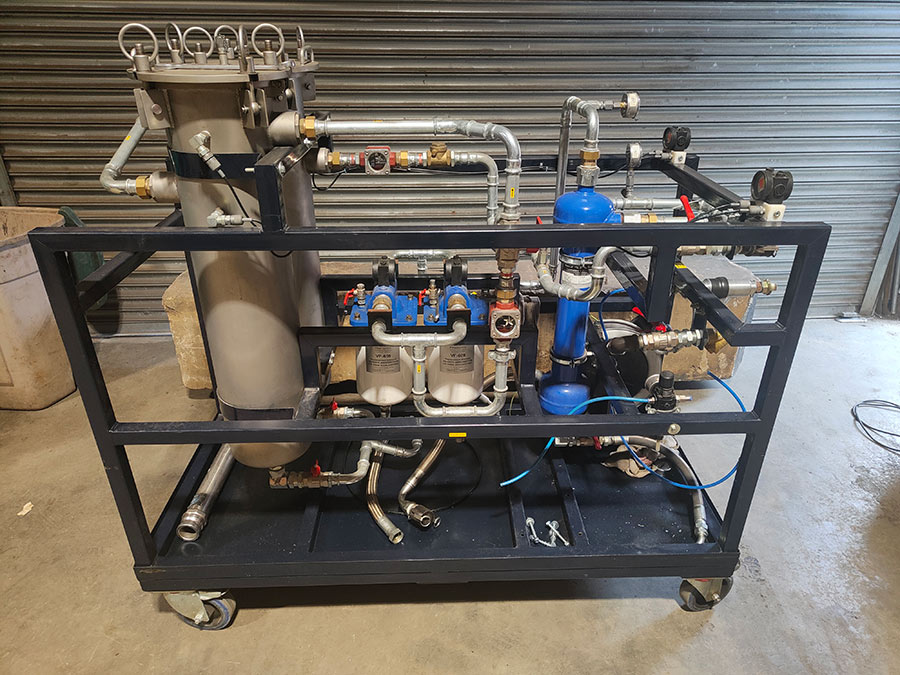

Diesel fuel polishing typically involves a multi-step process. The process begins by conducting a fuel analysis and sample to determine the degree of contamination and the best course of action. After the analysis, technicians employ filtering systems to remove impurities and contaminants from the fuel. These systems utilize various filter media and technology to eliminate and separate pollutants, while leaving pure diesel.

Regular fuel polishing offers several key benefits. In the first place, it increases the quality of fuel, which assures that engines get clean, constant fuel that allows them to burn efficiently. Additionally, it improves fuel efficiency as well as performance. This results in lower emissions and savings in cost. Additionally, it helps reduce the risk of engine failure and damage from the contamination of the fuel. By eliminating harmful substances, it improves the durability of engine components that are crucial which extends their service life, as well as decreasing the frequency of repairs and downtime.

Diesel polishing is a frequent process that offers many benefits in order to preserve the quality of your fuel. It helps remove water particles, sediments and microbial contaminants which can affect engine performance. The fuel’s quality is greatly improved because of the removal of these impurities via the polishing process used in diesel. This enhances the efficiency of combustion and reduces emissions. Second, regular diesel polishing reduces the risk of engine damage through preventing the clogging of fuel filters, injectors and other vital components. Polishing the fuel is essential to ensure the long-term durability of the storage system for fuel because it helps to reduce the accumulation of sludge corrosion, and other pollutants. Regular diesel fuel polishing is a great way to reap a range of advantages, including better engine performance, reduced costs, and increased reliability.

In addition, the services offered by fuel polishing can be tailored to meet the requirements of various industries and applications. Polishing the fuel is applicable to a range of applications, ranging from boats and backup engines to construction equipment and transportation fleets. Polishing the fuel is vital for industries that depend on an unreliable and uninterrupted power supply. It is also essential for those who work in harsh or remote environments where the quality of the fuel is at risk.

In summary, polishing the fuel is a critical procedure to ensure the quality and purity of diesel fuel. It improves engine performance, lowers maintenance costs and increases the life of equipment by removing pollutants and impurities. Making the investment in professional polishing services allows industries to protect their operations, improve efficiency, and reduce the risk of contamination of fuel. Fuel polishing is an efficient tool that is able to boost the efficiency of diesel fuel.